Industry Collaboration in Exhaust System Innovation: OEMs, Suppliers, and Academia

goldbet7.com login, radha exchange, 11xplay online:Industry Collaboration in Exhaust System Innovation: OEMs, Suppliers, and Academia

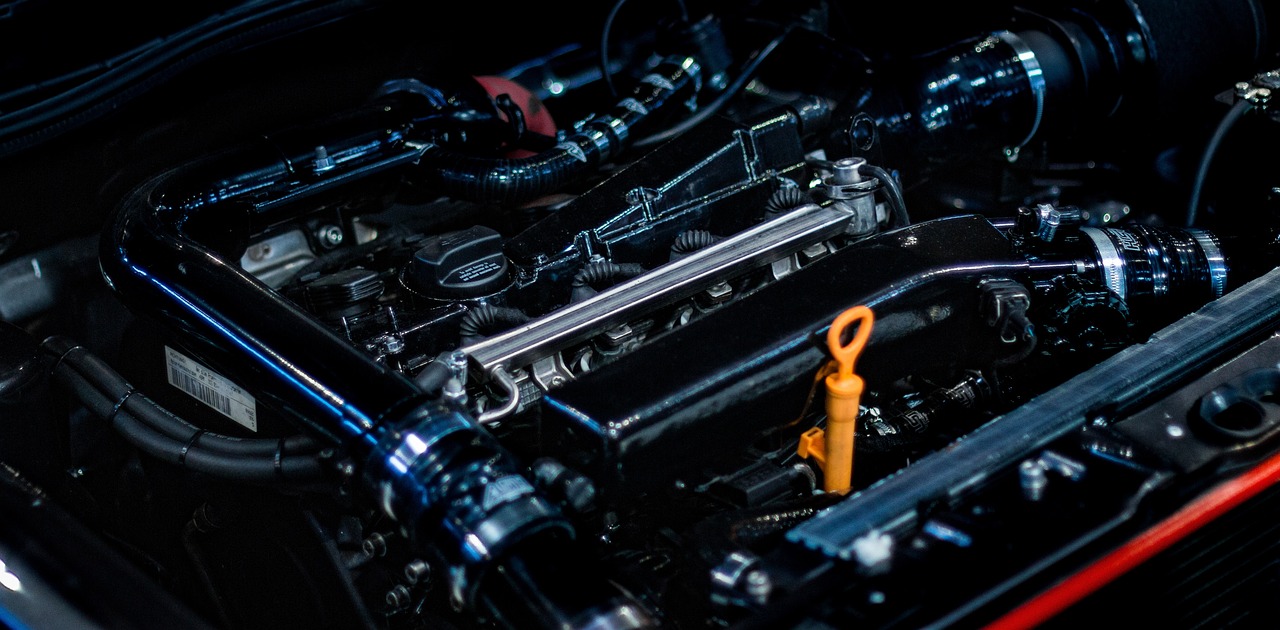

In today’s competitive automotive industry, innovation is key to staying ahead of the curve. One crucial component of a vehicle’s performance and environmental impact is its exhaust system. Collaborations between Original Equipment Manufacturers (OEMs), suppliers, and academia have proven to be a driving force behind groundbreaking advancements in exhaust system technology.

The exhaust system plays a vital role in reducing emissions, enhancing fuel efficiency, and improving overall vehicle performance. As regulatory standards become more stringent, the demand for innovative exhaust system solutions has never been higher. This is where industry collaboration comes into play.

By leveraging the expertise and resources of OEMs, suppliers, and academia, companies can pool their knowledge and capabilities to develop cutting-edge exhaust system technologies. These collaborations not only benefit individual companies but also the industry as a whole, driving progress and shaping the future of automotive engineering.

Benefits of Industry Collaboration in Exhaust System Innovation

1. Enhanced R&D Capabilities: Collaboration between OEMs, suppliers, and academia allows for the sharing of resources, knowledge, and expertise. This pooled R&D capability enables companies to tackle complex challenges and develop innovative solutions more efficiently and effectively.

2. Accelerated Innovation: By working together, companies can tap into a broader range of ideas and perspectives, accelerating the pace of innovation. Collaborations foster creativity and encourage out-of-the-box thinking, leading to breakthroughs that may not have been possible in isolation.

3. Cost-Effective Solutions: Sharing resources and expertise through industry collaborations can help reduce costs associated with R&D and product development. By working together, companies can leverage economies of scale and streamline processes, ultimately delivering cost-effective solutions to market.

4. Access to Specialized Knowledge: Academia brings valuable research and technical expertise to industry collaborations, providing companies with access to cutting-edge advancements in exhaust system technology. By partnering with academic institutions, companies can stay at the forefront of industry trends and developments.

5. Competitive Advantage: Collaboration in exhaust system innovation can give companies a competitive edge in the market. By working together to develop groundbreaking technologies, companies can differentiate themselves from competitors and enhance their reputation as industry leaders.

Challenges of Industry Collaboration in Exhaust System Innovation

1. Intellectual Property Concerns: Protecting proprietary information and intellectual property rights can be a challenge in industry collaborations. Companies must establish clear agreements and protocols to safeguard their innovations while still fostering open communication and collaboration.

2. Coordination and Communication: Effective collaboration requires strong coordination and communication among all parties involved. Ensuring that goals, timelines, and responsibilities are clearly defined is essential to the success of joint projects.

3. Cultural Differences: OEMs, suppliers, and academia may have different organizational cultures, priorities, and decision-making processes. Bridging these differences and building trust among collaborators can present challenges but is crucial for successful partnerships.

4. Regulatory Compliance: Developing exhaust system technologies that meet stringent regulatory standards requires careful attention to compliance and certification requirements. Industry collaborations must navigate these regulatory challenges to ensure that innovations are market-ready.

5. Resource Allocation: Balancing the needs and priorities of multiple stakeholders in industry collaborations can be a complex task. Managing resources, timelines, and budgets effectively is essential for ensuring that projects stay on track and deliver results.

Case Study: Collaborative Research on Next-Generation Exhaust Systems

One example of successful industry collaboration in exhaust system innovation is a recent research project that brought together a leading OEM, a specialized supplier, and a prominent academic institution. The goal of the project was to develop a next-generation exhaust system that optimized emissions control, fuel efficiency, and performance.

The OEM provided expertise in vehicle design and manufacturing, the supplier contributed specialized knowledge in exhaust system components, and the academic institution brought research capabilities and technical insight to the collaboration. By combining their strengths, the partners were able to make significant advancements in exhaust system technology.

Through comprehensive testing and analysis, the collaborative research project resulted in the development of an innovative exhaust system that exceeded regulatory standards, improved fuel efficiency by 10%, and enhanced vehicle performance. The partners were able to leverage their combined expertise to overcome technical challenges and bring a groundbreaking product to market.

FAQs

Q: How do OEMs benefit from industry collaborations in exhaust system innovation?

A: OEMs can leverage the specialized knowledge and resources of suppliers and academia to develop cutting-edge exhaust system technologies that improve vehicle performance and meet regulatory standards.

Q: What role does academia play in industry collaborations?

A: Academia brings valuable research capabilities and technical expertise to industry collaborations, providing companies with access to the latest advancements in exhaust system technology.

Q: What are some challenges of industry collaborations in exhaust system innovation?

A: Challenges include intellectual property concerns, coordination and communication issues, cultural differences among collaborators, regulatory compliance requirements, and resource allocation complexities.

Q: How can companies overcome challenges in industry collaborations?

A: Clear agreements and protocols can help protect intellectual property, strong coordination and communication are essential for effective collaboration, bridging cultural differences requires building trust among collaborators, regulatory challenges can be navigated through careful attention to compliance, and effective resource management is crucial for project success.

Q: What are some benefits of industry collaborations in exhaust system innovation?

A: Benefits include enhanced R&D capabilities, accelerated innovation, cost-effective solutions, access to specialized knowledge, and a competitive advantage in the market.

In conclusion, industry collaboration in exhaust system innovation is a powerful driver of progress and advancement in the automotive sector. By bringing together OEMs, suppliers, and academia, companies can tap into a wealth of expertise and resources to develop groundbreaking technologies that shape the future of vehicle performance and sustainability. Collaborative research projects, such as the case study highlighted, demonstrate the transformative impact of industry partnerships in driving innovation and establishing a competitive edge in a rapidly evolving market.